Does Basic Copper Chloride Source Impact Grow-Finish Performance?

go.ncsu.edu/readext?832483

en Español / em Português

El inglés es el idioma de control de esta página. En la medida en que haya algún conflicto entre la traducción al inglés y la traducción, el inglés prevalece.

Al hacer clic en el enlace de traducción se activa un servicio de traducción gratuito para convertir la página al español. Al igual que con cualquier traducción por Internet, la conversión no es sensible al contexto y puede que no traduzca el texto en su significado original. NC State Extension no garantiza la exactitud del texto traducido. Por favor, tenga en cuenta que algunas aplicaciones y/o servicios pueden no funcionar como se espera cuando se traducen.

Português

Inglês é o idioma de controle desta página. Na medida que haja algum conflito entre o texto original em Inglês e a tradução, o Inglês prevalece.

Ao clicar no link de tradução, um serviço gratuito de tradução será ativado para converter a página para o Português. Como em qualquer tradução pela internet, a conversão não é sensivel ao contexto e pode não ocorrer a tradução para o significado orginal. O serviço de Extensão da Carolina do Norte (NC State Extension) não garante a exatidão do texto traduzido. Por favor, observe que algumas funções ou serviços podem não funcionar como esperado após a tradução.

English

English is the controlling language of this page. To the extent there is any conflict between the English text and the translation, English controls.

Clicking on the translation link activates a free translation service to convert the page to Spanish. As with any Internet translation, the conversion is not context-sensitive and may not translate the text to its original meaning. NC State Extension does not guarantee the accuracy of the translated text. Please note that some applications and/or services may not function as expected when translated.

Collapse ▲Results suggest basic Cu chloride enhances finishing throughput.

Micronutrients, such as copper (Cu), account for a very small portion of pig diets. Yet Cu source can have a sizable impact on grow-finish performance. Differences exist between differing forms of Cu such as Cu sulfate, basic Cu chloride (BCC) and organic sources of Cu. Yet within Cu form, few studies have looked to establish differences. Therefore, the objective of the current study was to evaluate differences in grow-finish performance between two sources of BCC, IntelliBond C and another hydroxy chloride mineral (OHTM) BCC in the presence of a Cu sulfate control diet.

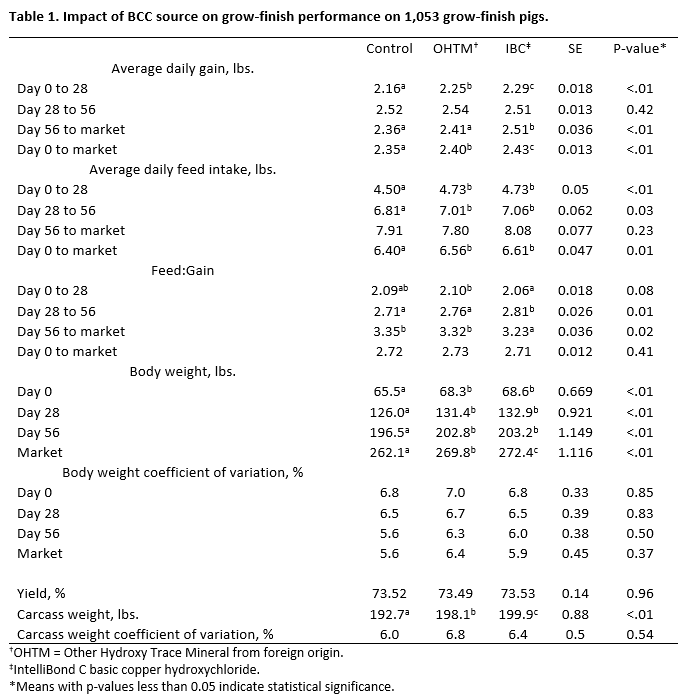

Pigs from second parity sows at the North Carolina Department of Agriculture Tidewater Research Station (Plymouth, NC) were used. Sows were Landrace x Large White composites mated to Smithfield Premium Genetics’ Duroc boars. Hence, pigs were 50% Duroc and 50% whiteline. At weaning, piglets were vaccinated for PCV2 and Ileitis and placed in a nursery. At completion of the nursery phase, gilts and barrows (n=1,053) were randomly allocated within sex to one of 117 finishing pens (9 pigs per pen, 7.45 ft2 per pig). Treatments included a control (15 ppm), IntelliBond C (fed at 150 ppm Cu) and an OHTM Cu (fed at 150 ppm Cu). Treatments were fed from weaning to market and finisher entry to market in replicates 1 and 2, respectively. Housing consisted of fully slatted floors and natural ventilation. Animals were transported to a harvest facility and carcass weights collected. Data was analyzed in SAS using PROC GLM. Traits included pig weight, average daily gain, average daily feed intake, feed efficiency, variation in body weight, carcass weight and yield. Replicate, barn location, sex and diet were included in statistical models. Pen was the experimental unit. Results from the study are shown in Table 1.

Both sources of BCC outperformed the Cu sulfate control diet, both having increased average daily gain driven by increased average daily feed intake. Yet pigs fed IntelliBond C had significantly greater (P=0.01) average daily gain when compared those fed the OHTM Cu. The enhanced growth of IntelliBond C was driven by numerically greater average daily feed intake and improved feed efficiency. The improved gain resulted in a higher body weight at marketing and persisted in a higher hot carcass weight for basic copper chloride sources compared to Cu sulfate and for IntelliBond C compared to OHTM Cu (P<0.05).

How is it possible for two sources of BCC to differ? While we are not sure we fully understand the underlying biology, the processes by which IntelliBond C and the OHTM copper chloride are manufactured differ. Taken together, results suggest BCC enhances finishing throughput and that performance differences exist between BCC sources.

Sources: Mark Knauer, Chris van de Ligt, North Carolina State University, Micronutrients